Ex-Proof Cranes

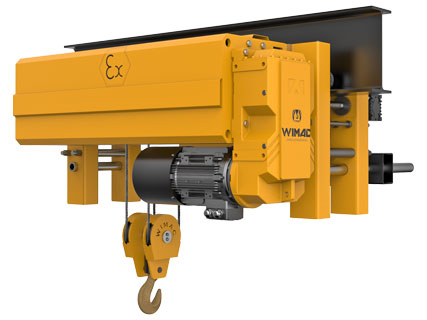

In a way that can be easily and safely installed and used in all underground and above-ground industrial environments and in all types of cranes (single /double beam overhead cranes, single /double beam gantry cranes, jib cranes, wall cranes, etc.) they can be produced.

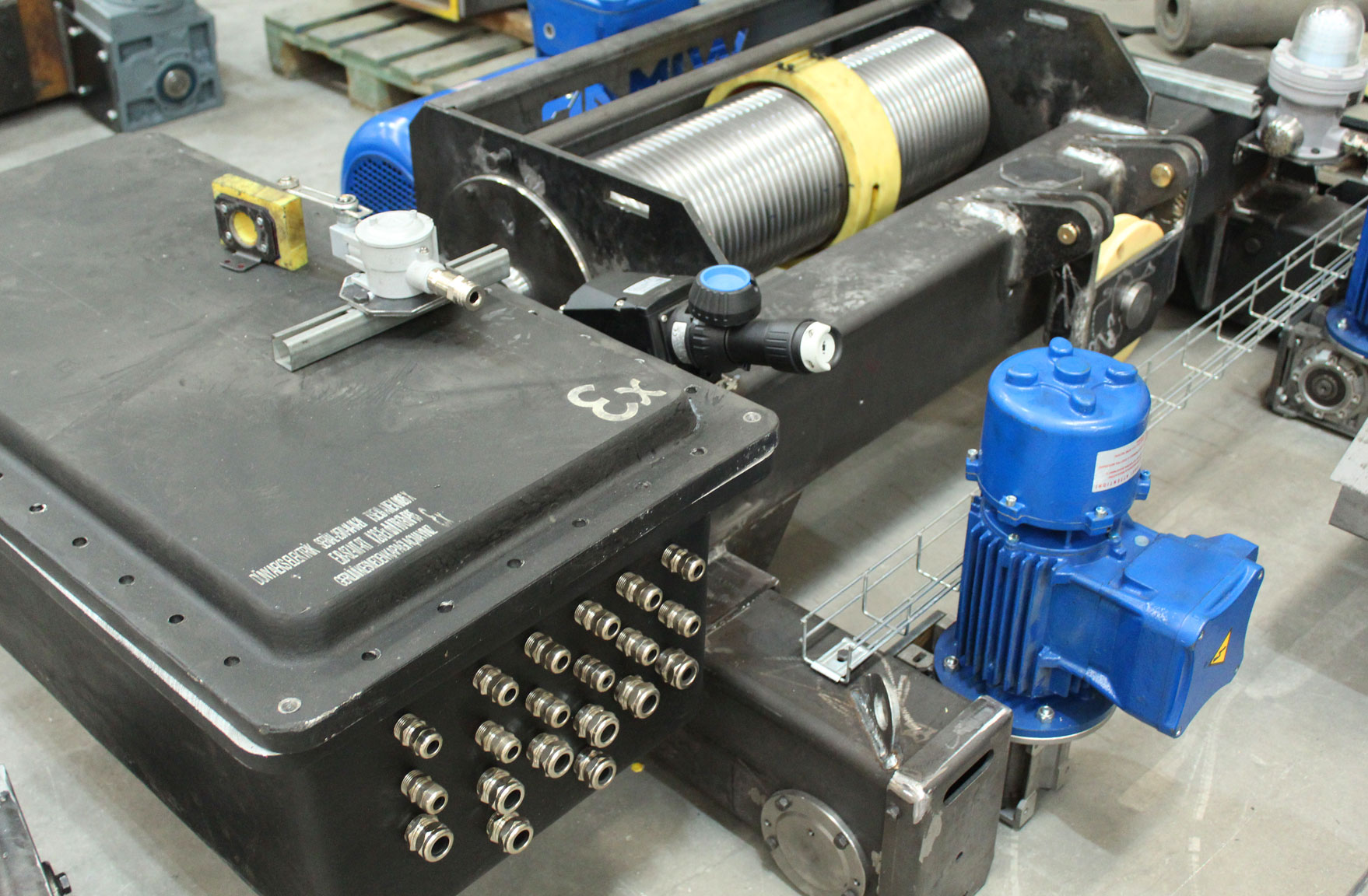

Ex-proof cranes are explosion-proof cranes. The purpose here is to use it in environments where flammable and explosive substances are present (January mines, paint shops, gunpowder plants, oil and petroleum products enterprises, etc.).) to minimize the risks that may arise from the crane. It provides high safety with carefully selected components taking into account the areas of use.

WIMAC CRANE ex-proof cranes are designed and manufactured to provide high processing performance and maximum uptime. Thanks to its modular structure, it is easy and fast to install and saves you time. So your work will not stop for a long time and you can start using it as soon as possible. It provides high accessibility for safe control and maintenance. It minimizes your maintenance costs with its quality and correctly selected components.

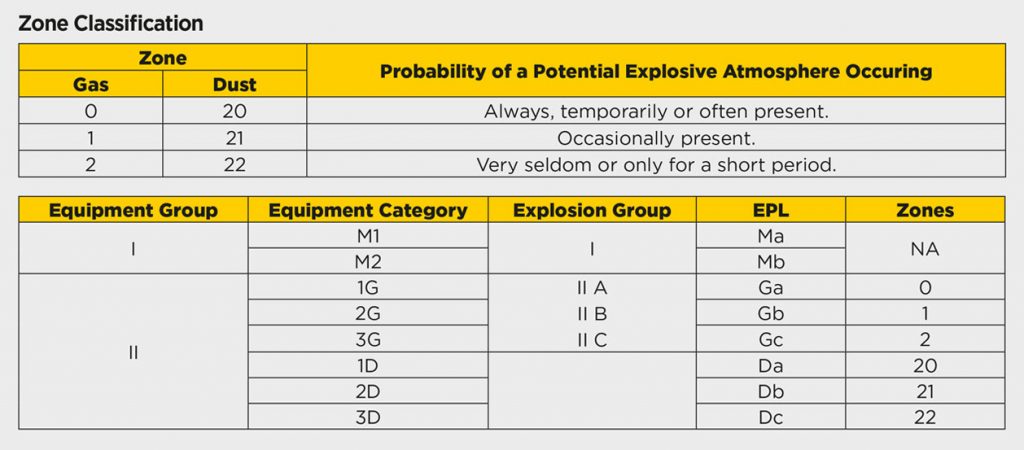

Explosive gases can explode with an ignition source such as a spark when they encounter oxygen in the air, as well as catch fire from the surface temperatures of equipment located in the same environment. Flammable powders are also suspended in the air or collapsed on a surface, while any spark that may come from outside, ignition, surface temperature, etc. they can burn or explode with it. G Gas for Steam and Gas environments), D (Dust) coding is performed for dust environments.

Usage Area

1. Chemical industry

2. Refineries

3. Gas supply

4. Pharmaceutical industry

5. Wastewater treatment

6. Distilleries

7. Mining

8. Production plants

Precautions that can be taken against combustion and explosions in industrial environments have been determined by various standards and regulations in the world.

1. First, determine whether the crane will operate underground (Device Group – I) or above ground (Device Group – II).

2. Determine the device category and explosive atmosphere environment (M1, M2, 1G, 2G, 3G, 1D, 2D, 3D)

3. Determine the explosive media group. (I,IIA,IIB,IIC,IIIA,IIIB,IIIC)

4. Determine the temperature class.

5. Determine your other special requests.

You can contact our technical office for a safe, ideal and correct choice.